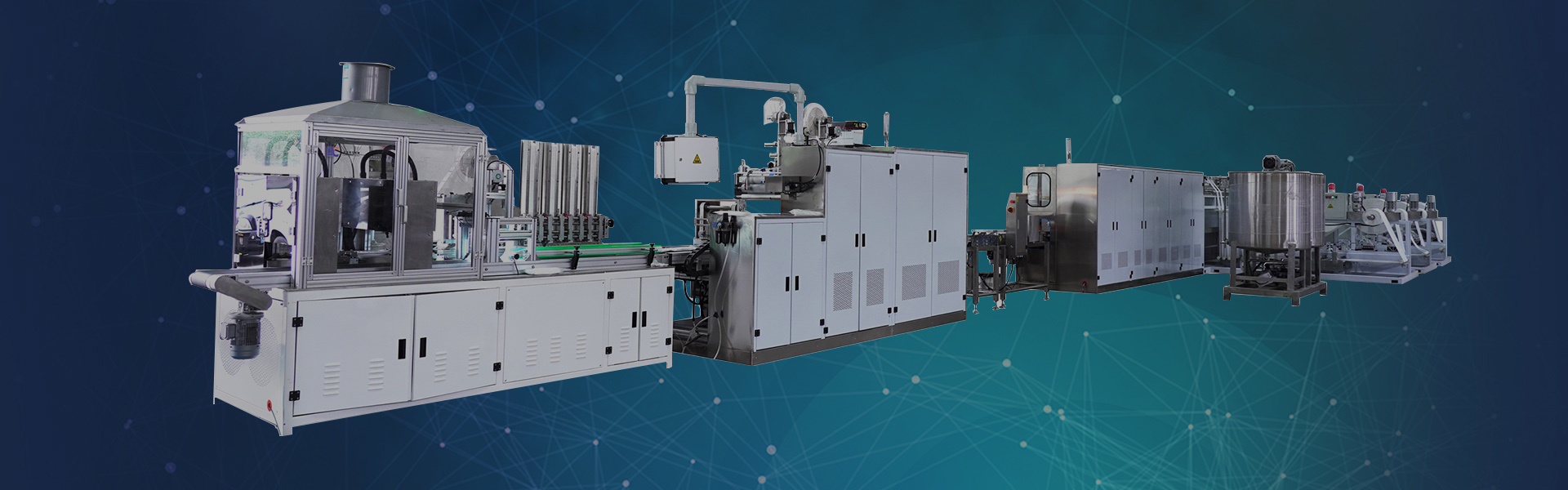

DC-2020D Full-auto Wet Wipes Machine

Item Number:

DC-2020D

Features

Detail

Product video

technical parameter

DC-2020D Full-auto 5-30 pieces Wet Wipes Machine

Features:

DC-2020D wet wipes machine specializes in the production of portable wet wipes, the number of which can be adjusted from 5 to 30 pieces, to meet the needs of small packaging that people carry with them when they go out. Types of wipes include baby wipes, cosmetic wipes, specialty wipes and cleaning wipes. DC-2020D is a double-channel design, man-machine interface, convenient and fast parameter setting, simple operation of the production line, high stability, and stable speed of 60-70 bags/min.

1.Product description:

DC-2020D wet wipes machine specializes in the production of portable wet wipes, the number of which can be adjusted from 5 to 30 pieces, to meet the needs of small packaging that people carry with them when they go out. Types of wipes include baby wipes, cosmetic wipes, specialty wipes and cleaning wipes. DC-2020D is a double-channel design, man-machine interface, convenient and fast parameter setting, simple operation of the production line, high stability, and stable speed of 60-70 bags/min.

2. Process flow:

Automatic unwinding → automatic slitting → corner pulling → vertical folding → synchronous cloth feeding → humidification cutting → stacking counting → finished product conveying

3. Other configuration

Pneumatic component brand: Taiwan AirTAC

Key bearing brand: Japan NTN/NSK

Transmission mode: closed gearbox + synchronous belt + universal coupling

Motor control: each motor can be started and stopped individually, operated on the touch screen

Emergency stop button: 3 emergency stop buttons; 1 pull wire for emergency stop; when the emergency stop button is pressed, the equipment stops running immediately.

Operation interface: LCD touch screen; real-time setting of various production parameters; daily output data recording and storage functions; providing MES data interface; remote assistance and monitoring functions, etc.

The electrical control mode has two modes, automatic and manual, to meet the needs of production process control

Equipment fail-safe prompt: automatic shutdown or alarm prompt

Layout

Feedback

QuanZhou DACHANG Paper Machinery Manufacturer Co.,LTD.

No.28, Zishan Road, Jiangnan Hi-tech Industrial Park II, Licheng District, Quanzhou City, Fujian Province, China (362000)

Copyright 2021 QuanZhou DACHANG Paper Machinery Manufacturer Co.,LTD.